Electroless Nickel - what makes it special?

Conventional Electrodeposited Nickel

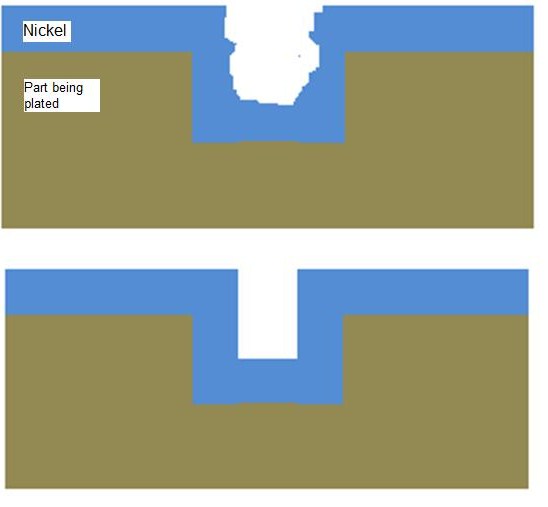

With conventional electrodeposited Nickel, the plating is uneven in holes and recesses because the flow of positive ions from the Nickel anode to the negative cathode (the part being plated) is directional and some places end up “shadowed” and so do not get enough nickel deposited there

Electroless Nickel

Electroless nickel differs in that catalysts in the solution cause the nickel to be laid down on the parts being plated by a chemical reaction, so everywhere the solution goes, a layer of Nickel will be evenly deposited on the surface, even into holes and recesses. This makes it very suitable for today’s complex precision engineered parts, such as injection molds. It can be heat treated and is very durable so can be used on parts subject to wear such as central heating pump bearings. Also historically, Nickel was used on vintage motorbikes and cars before Chrome and can be polished to a high finish as well as giving excellent protection.